Transfer Chute Design and Fabrication

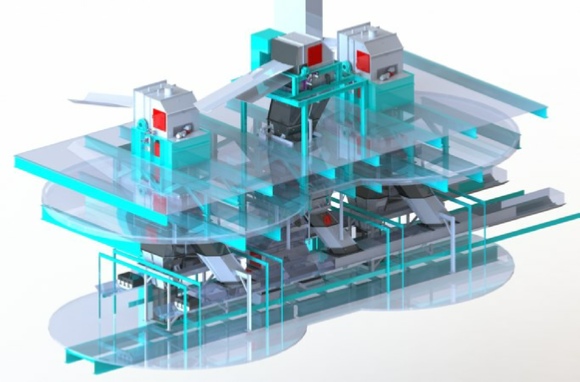

PME Services offer the complete range of services for design, fabrication and installation of conveyor transfer chutes. Our services include:

- Analysis of the material being conveyed and subsequent selection of the concept, be it rock box, ledge, slide or easy flow.

- Design optimisation using 3D parametric design software and Discreet Element Modelling (DEM -

ROCKY) - Detail drawings

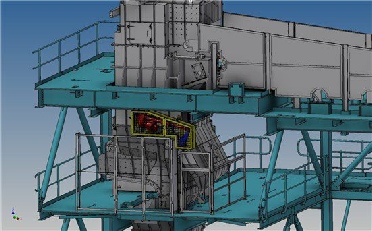

- Fabrication

- Site measurement including 3D laser scanning for complex installations

- Installation Management

Because this is all done ”in house” and fabrication is in Pretoria a rapid turnaround is possible because there are typically minimal delays between the finalization of concept, to detail drawings and fabrication.

What is D.E.M.?

PME Services has invested in two software technologies which enable rapid optimizations of transfer chute designs. As well as 3D design software, when interfaced with the virtual simulation packages ROCKY are required.

ROCKY is a family of numerical modelling techniques and equations specifically designed to solve problems in engineering and applied science that exhibit gross discontinuous mechanical behaviour such as bulk material flow. ROCKY specifically models the dynamic motion and mechanical interactions of each body or particle throughout a simulation and provides a detailed description of the positions, velocities and forces acting on each body and/or particle at discreet points in time during the analysis.

By studying this predicted behaviour of these particles through various chute geometry – velocities, build up, pressures and the impact points – we are able to make changes to the geometry to achieve the design objectives.

ROCKY is therefore a tool which designers can use to improve the chances of getting the best possible design in a transfer chute.

To achieve consistently successful chute designs a designer still has to have good knowledge of chute design first principles, a good understanding of the variable conditions that the chute is to operate under and a good understanding of material properties, maintenance procedures and installation techniques.

Benefits & Futures

- Engineered to help prevent dust generation

- Compact design with rounded corners

- No pinch points

- No skirt, seals or belt support

- No hoods or tail boxes

- Module component design

- Adjustable to ensure centre loading