Oil analysis provides early indications of equipment wear mechanisms and identifies the root causes of corrosion.

On-

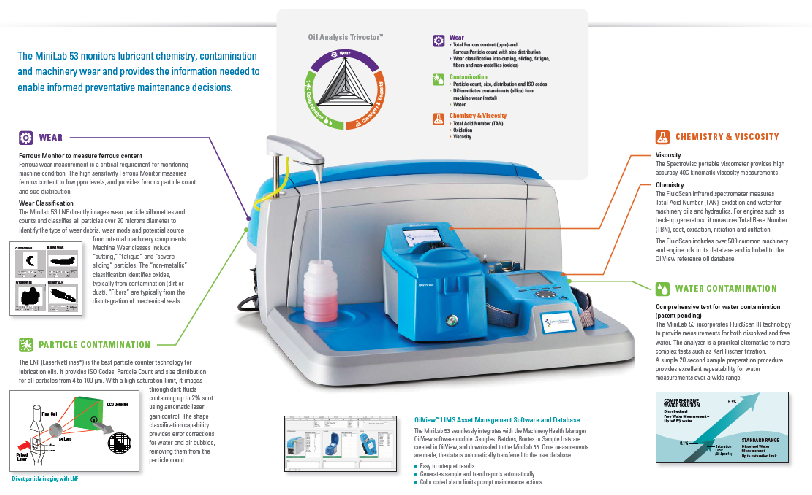

The MiniLab 53 delivers comprehensive on-

Increase equipment availability by reducing unexpected downtime

- Early identification and trending of machinery wear and failure modes allows preventative maintenance before a catastrophic failure occurs

- MiniLab 53 measures oil chemistry, sources of contamination and machinery wear debris

- Makes it easy to track and trend the key oil parameters necessary for optimising Machinery Health™

Reduce maintenance costs

- Extends component lifetime through effective contamination control

- Proactively schedule maintenance based on the predictive analytics of machine wear, rather than reacting to unexpected component failure

- Extending oil drain intervals based on oil chemistry

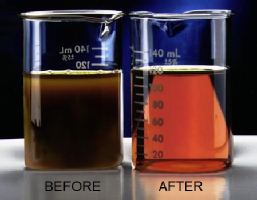

- Verify new oil is the right oil and fit for use

- Features SpectroVisc, a portable viscometer and FluidScan, a handheld spectrometer, allowing QA testing at the receiving dock and in-

service testing at the machine - Verify that it is the right oil and fit-

for- use

Fast, simple and easy to use

Comprehensive oil analysis in less than 10 minutes Can be operated by plant staff, no chemist required Easy to interpret results and maintenance actions

- Generates sample and trend reports automatically

- Colour coded alarm limits prompt maintenance actions

The MiniLab 53 addresses the questions:

- Is it the right oil?

- Is the oil clean?

- Is it dry?

- Is it fit for use?

- And most importantly:

Is the machine in good condition?