The Industrial use of Fibreglass Reinforced Polyester (FRP)

The unique properties of Fibreglass make it suitable for a wide range of Industrial product applications and offer great advantages compared to other materials. Fibreglass (FRP) is also engineered for a wide range of corrosive and abusive environments and is intended to save customer's time and money.

The versatility, strength & durability, the ability to stand up to corrosive chemicals, also in higher temperatures, the non-

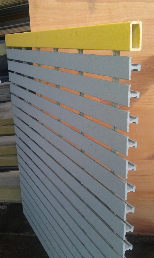

Fibreglass is a superior building material, with very high strength per dollar cost. Some of the Industrial applications are:

Piping and fittings (from 1" to 10' feet in Diameter), tanks, enclosures, consoles, buildings, Automotive parts and transportation vehicles, cabinets and large storage cabinets, military applications, Odour & acid control systems, flumes, concrete forms, manholes, furan fabrications, utility poles, swimming pools, duct systems, split control cabinets, weirboxes, flumes, aerospace components and fittings, wind generators, Industrial coolers and a lot more.

We can manufacture fibreglass products of any size for any Industrial project. Bring your plans or ideas and we will work with you, applying our knowledge and experience, in the construction and design of your product. If needed we will work with you to develop prototypes or modify your existing design.

We can manufacture fibreglass products of any size for any Industrial project. Reinforced plastic (FRP) moulding & fabrication, corrosion resistant to acids or caustics, flame retardant, specializing in high strength to weight ratio fibreglass fabrications.

The unique properties of Fibreglass make it suitable for a wide range of product applications, and offer advantages that are not found in other types of construction. These advantages include:

Design Freedom

High degree of design flexibility. The practical uses of fibreglass are virtually endless, limited only by your imagination. Fibreglass opened many new avenues for creative designers. Its unique physical properties allow it to be easily tooled, moulded and manufactured to meet almost any specifications. Because there are few constraints on size, shape, colour or finish, the styling and appearance can take precedence over manufacturing costs.

Affordability

This design freedom and the easiness to work make fibreglass an economical alternative for the manufacture of any component or finished product in any quantity.

Versatility

The lightweight strength of fibreglass has always made it a popular choice for manufacturing. Fibreglass offers distinct advantages in a wide range of products; its reduced weight and maintenance make it attractive on architectural projects. More and more industries are discovering the benefits of its versatility.

Strength & Durability

High strength to weight ratio and high flexural strength. Fibreglass is an attractive lightweight material that builds strength into almost any finished product or component. Pound for pound fibreglass can be stronger than steel and sheet metals. Highly resistant to environmental extremes. Fibreglass is built to last. Dollar for dollar, fibreglass reinforced plastic products provide better performance than plain non-

Appearance

Fibreglass parts are gel-

Moulded Look

With sheet metal, you get a plain box. Fibreglass parts have sleek contours and a superior moulded appearance with high visibility colours.

Dielectric

Fibreglass is non-

Corrosion – Environmentally Tough

Fibreglass is non-

Sound Deadening

Fibreglass provides superior acoustical properties when compared to plastic or metal. Various type of sound deadening materials can be laminated between high strength layers of Fibreglass matte to achieve the preferred level of sound deadening.

Stability

Fibreglass exhibits the least amount of expansion and / or contraction when compared to plastic, wood, or metals. Fibreglass parts have excellent dimensional stability and will hold their shapes under severe mechanical and environmental stresses.

Low Maintenance

Fibreglass parts require very little maintenance – no rust, no painting, no wood rot. Tired of costly maintenance associated with repairing or replacing expensive equipment?

Move into the Future with Fibreglass!